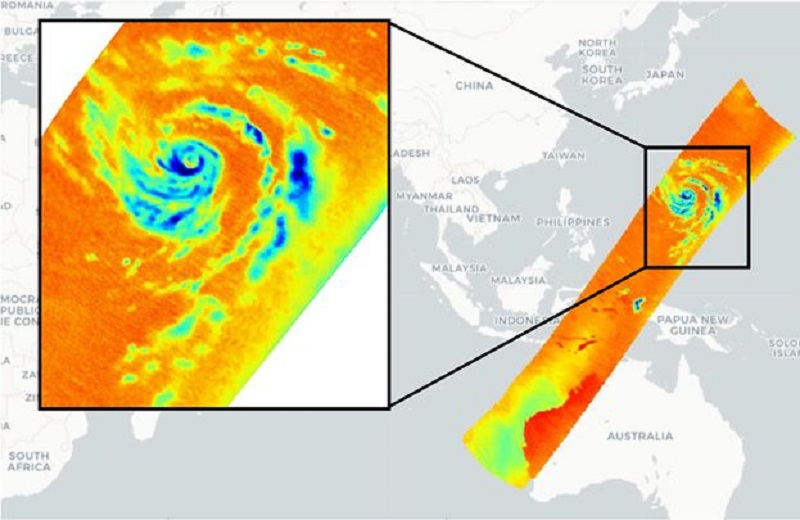

Orbital captured imagery of Typhoon Hagibis

Orbital Micro Systems (OMS), a leader in advanced instrumentation for small satellite missions and analysis-ready earth data intelligence, has released imagery of Typhoon Hagibis captured from its IOD-1 GEMS satellite.

The data shows the beginning of an eyewall replacement cycle, a process that occurs with particularly strong storms. During this scan, a core of warmer air – depicted as darker red colours on the right side of the storm – is being drawn into the centre of the storm.

This warmer air represents a temporary weakening of the storm as a prelude to the development of a new eyewall and further strengthening.

“The GEMS 118 GHz, 8 channel microwave radiometer delivered exceptional spatial resolution and sensitivity in providing ws, competitive with multi-billion-dollar government programs performing similar measurements,” said Michael Hurowitz, chief technology officer for OMS.

“These images validate the capability of OMS’ remote sensing technology and demonstrate the highest spatial resolution of any passive microwave temperature sounder in space on an operational mission.”

The raw data downlinked from the satellite was processed at OMS’s International Centre for Earth Data (ICED) located in Edinburgh, Scotland.

“Observed data from this satellite can be combined with information from government-owned systems to improve the accuracy of storm forecasts,” said Hurowitz.

“We are working with providers and partners to provide enhanced weather information that improves safety margins for people and businesses risking severe weather events.”