Resilient firms and economies: Unlocking growth in emerging markets

Resilience is like a bridge spanning a turbulent river. The waters below may surge unpredictably, but the bridge’s strength lies in its design, maintenance, and ability to withstand. The Resilience Consortium brings together governments, businesses, and multilateral development banks (MDBs) to strengthen resilience in emerging markets. Drawing on insights from […]

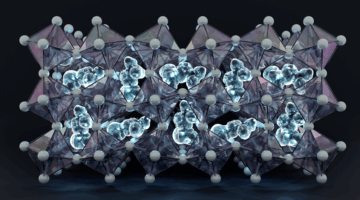

Quantum-inspired wireless technology could tackle 6G’s biggest challenges

Researchers at Monash University and The University of Melbourne have developed a quantum-inspired approach to optical wireless communication that promises to make 6G networks faster, more reliable and energy-efficient. As the world moves toward 6G, devices and networks will need to handle more data, faster, and in smaller spaces than […]

Ruled by engineers: how China gets things done, leaving the US in the dust

Mark Beeson, Adjunct Professor, Australia-China Relations Institute, University of Technology Sydney. In modern times, the world’s most powerful and influential states have also had the largest economies. When the United States overtook Britain in the early 20th century, it was only a question of time before it assumed international political […]

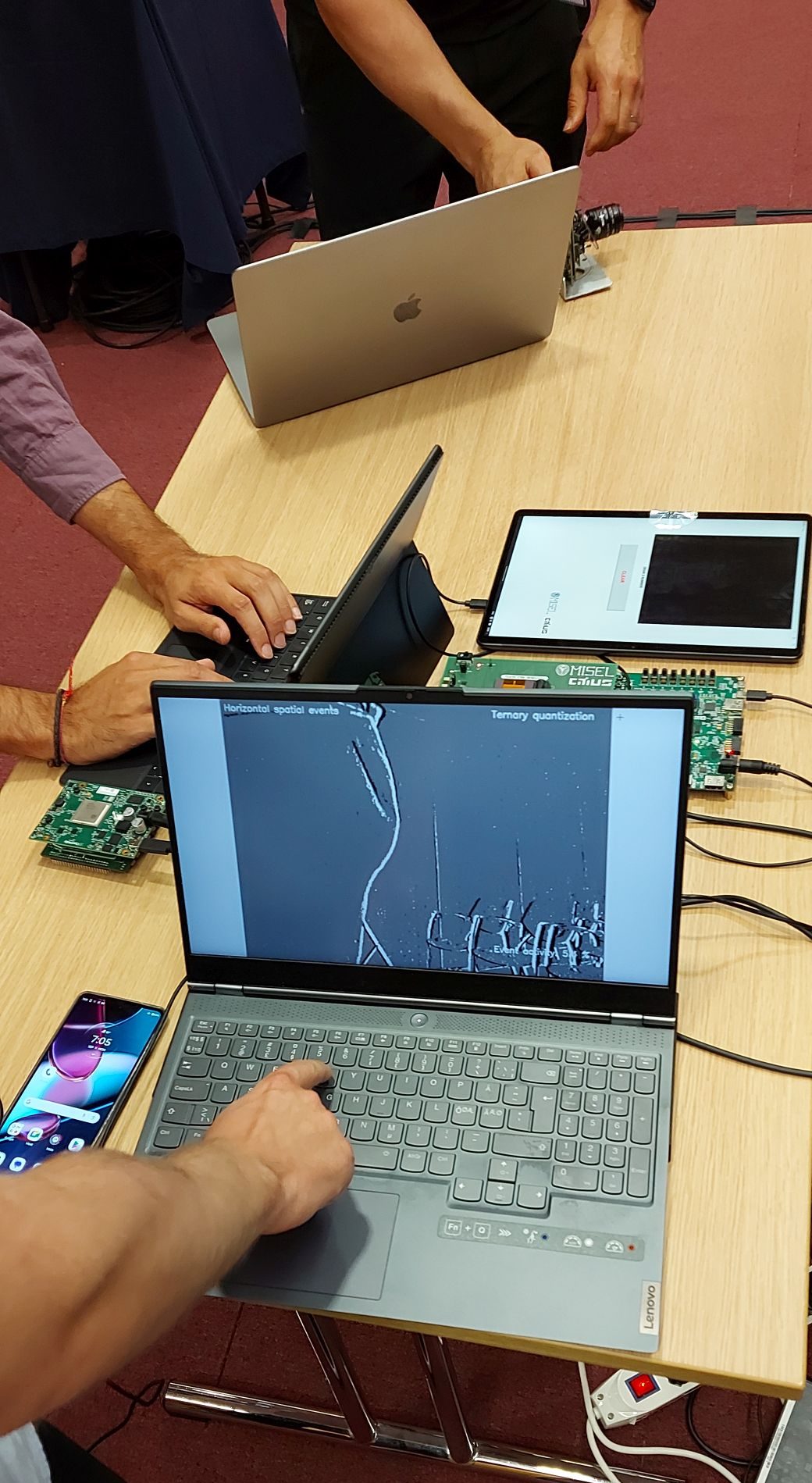

European researchers develop energy-efficient machine vision inspired by human eyesight and the brain

Drawing inspiration from human eyesight, a European research project led by VTT has developed machine vision mimicking the cooperation of the eye and nervous system, implemented as edge-computing circuits. Edge computing means processing data where it is generated and where the results of computing are needed. This enables, for instance, […]

Could a ‘grey swan’ event bring down the AI revolution?

Cameron Shackwell, Sessional Academic, School of Information Systems, Queensland University of Technology The term “black swan” refers to a shocking event on nobody’s radar until it actually happens. This has become a byword in risk analysis since a book called The Black Swan by Nassim Nicholas Taleb was published in 2007. A frequently cited […]

Top tips for securing the investment your manufacturing business needs to grow

-Andrew Mamonitis, Vice President – APAC, Manufacturing Division, ECI Software Solutions It pays to optimise your processes and practices before expanding or bringing an external investor on board. Despite challenging conditions, manufacturing businesses are looking for ways to grow their share of the domestic market and pursue potentially lucrative […]

Research shows CPG leaders are investing in AI and talent to stay competitive

Rockwell Automation Report finds CPG Industry prioritising innovation over cost cutting Rockwell Automation has announced the results of the 10th annual State of Smart Manufacturing Report: Consumer Packaged Goods (CPG) Edition. The findings highlight how manufacturers are placing greater importance on innovation, workforce development, and long-term growth strategies. The CPG […]

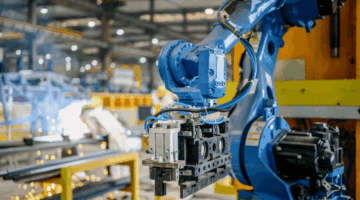

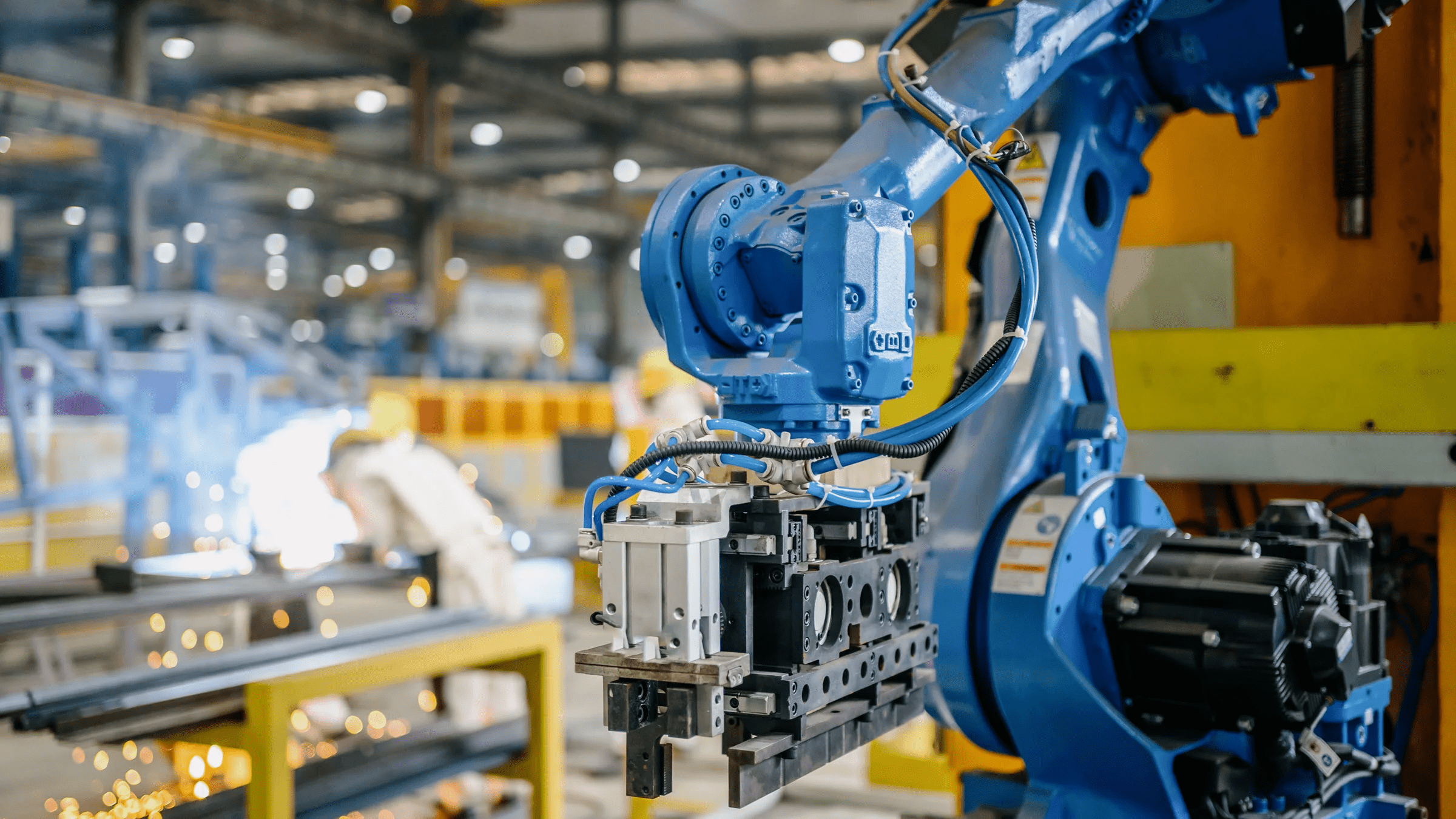

Hands free tool changes for smarter machining

Peter Pettersson, Sandvik Coromant Imagine a factory where the lights are off, not because no one is home, but because automated systems are working around the clock to keep production lines running with minimal human intervention. These futuristic setups are quickly becoming a reality, with touchless tool changes at the […]

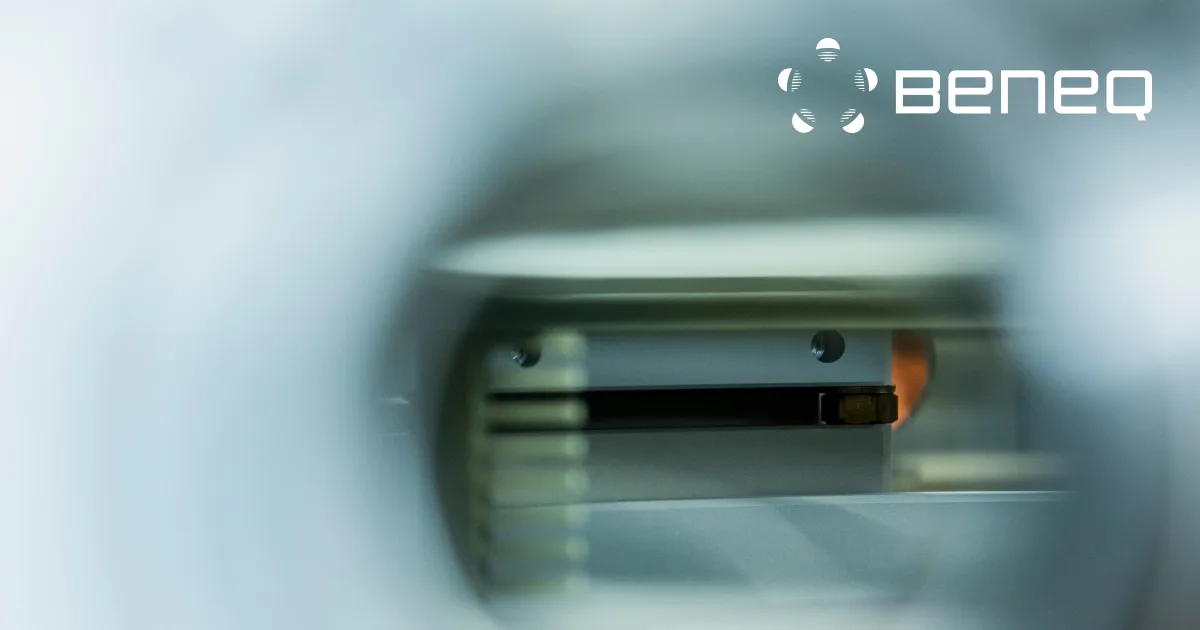

Beneq launches Transform XP – Redefining atomic control in ALD

Second-generation platform delivers advanced control, in-cycle annealing, and high-throughput performance for Wide Bandgap power and RF device manufacturing Beneq introduces the Beneq Transform XP, a second-generation ALD platform developed to meet the performance demands of Wide Bandgap (WBG) power and RF device technology development and manufacturing. Building on the proven […]

Jobs and the future of work

How to build the skills needed for the age of AI AI is changing how we work and what skills workers need to thrive in a world of intelligent machines and cognitive computing. Only a sliver of education initiatives are devoted to AI and these are not yet integrated into […]

Agents for growth: Turning AI promise into impact

As CEOs and CMOs ask where AI is moving from hype to real results, frontrunners demonstrate that tighter human–AI collaboration and sharper governance is required. A global retailer sees demand for a top product surge in one region while inventory piles up in another. Within seconds, a team of AI agents […]

Using AI to enable scalable, autonomous operations

By Troy Mahr, director – Kalypso. Kalypso – acquired by Rockwell Automation in 2020 – is a diverse team of consultants, innovators, strategists, data scientists and technologists. What we consistently hear from industry leaders is the need for real-time visibility across their global operations, which is key to ensuring their operations […]

Emerson’s next-generation of industrial PCs for AI-enabled automation

New PACSystems IPCs combine latest generation of industrial-rated processors with optimised cooling and pre-loaded software to simplify advanced computing and integration. Emerson has the PACSystems IPC 6010, IPC 7010, and IPC 8010 industrial computing platforms. This new line expands Emerson’s family of high-performance industrial personal computer (IPC) models for demanding applications, including artificial intelligence, machine learning and advanced analytics. PACSystems IPCs feature the first CPU in the latest generation of processors designed specifically to support AI enabled capabilities such as predictive maintenance, process optimization, quality inspection, decision support, supply chain management and more. Critical digital transformation applications require reliable and ruggedised computing platforms, with the high level of performance needed to support data collection, protocol conversion, historisation, and analytics for real-time optimisation and visualszation capabilities. The new PACSystems line features significant performance updates and more options to develop solutions for challenging industrial applications, with a range of functionality and price points to support scalable operations and lower cost-of-ownership. The new line of IPCs use the latest generation of soldered industrial-rated 13th Generation Intel Core Processors with up to 64 GB soldered ECC memory, for maximum resistance against shock and vibration. Their compact form factor employs fan-less cooling for an extended operating temperature range up to 70 degrees Celsius, with thermal monitoring and an optional fan available for high-temperature environments. PACSystems IPCs benefit from Emerson’s patented vibration and thermal technologies to boost reliability and extend deployment life.With solid-state drive (SSD) storage options ranging up to 4 terabytes, multiple gigabit Ethernet interfaces, up to four PCIe® slots, and other interfaces, PACSystems IPCs can be tailored to deliver high-performance computing required for vision systems, advanced analytics, data processing, historization/visualization, and other similarly rigorous functions for process optimisation and improved operational insight. Available pre-installed, pre-licensed operating systems with edge and visualisation software help to […]