mimic joins race to develop first AI-driven collaborative robot

The race to develop the first commercially available humanoid robot has been primarily concentrated in the US – until now.

Mimic, a Switzerland-based startup, is challenging US dominance and joining the robotics race to be the first to take a robotic arm and humanoid hand combination to market using generative AI, as it raises a pre-seed round of $2.5M.

mimic’s $2.5M round is led by early stage Swiss investor Founderful, together with participation from German-based fund another.vc, UK-based Tiny.vc and an all-star lineup of specialised angel investors.

Spinning out from the research university ETH Zurich, mimic was founded by researchers Elvis Nava, Stefan Weirich,Stephan-Daniel Gravert and Benedek Forrai in 2024.

The founding team were working at the intersection of robotics and AI under Professor Robert Katzschmann’s Soft Robotic Labs when they became increasingly convinced that the latest developments in large scale generative AI models would upend a multitude of industries, beyond just language and image generation.

The team set out to develop a foundation model for robotic manipulation and quickly realized how much value their idea held to revolutionise the way robotics fit into our everyday lives and economy.

Today, global labour shortages are rocking businesses across multiple sectors and employers are struggling to find, hire and retain workers.

Against the backdrop of a pronounced shift in work preferences, like reduced hours and enhanced flexibility to work from home, lab or shortages are especially severe in the case of menial, repetitive, and demanding manual tasks.

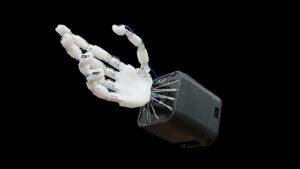

mimic plans to ease these shortages with dexterous, human-like robotic hands that fit seamlessly into existing manual labour workflows, driven by state-of-the-art AI models trained directly from human demonstrations.

This solution will enable a robot with humanoid hands to understand and imitate any behaviour, simply by watching a human perform it.

This marks a departure from conventional robotic solutions, which focus on being purpose-built for narrow use cases. Since each use case requires expensive ad-hoc engineering and comprehensive pre-programmed movements, robots are only able to complete the narrowly specific task they are designed for.

In contrast, mimic is developing robots with a unified, general- purpose approach to achieve a variety of tasks with a single robot design.

mimic’s robots will be powered by a foundation AI model, meaning they will be able to reason and understand the physical world. The downstream effect is that robots can execute tasks with minimal demonstrations and without requiring expensive, complicated programming by engineers for each new task.

These robots are designed for any industry employing workers in repetitive but hard-to-automate tasks involving complex motor skills.

Already, the team has been approached by a wide range of initial customers, from supermarkets, industrial baking and gastronomy to manufacturing, recycling and pharmaceutical lab automation.

“Conventional automation leaves a huge gap of tedious, low to medium volume manual labour tasks that often fall under the table because they are too complex or not economical to automate. For companies from retail to manufacturing, it becomes increasingly harder to find the right staff for these tasks. Taking AI-driven robotic manipulation to the next level, we can now address these challenges with unparalleled flexibility and ease of use”, says co-founder Stefan Weirich.

Looking forward, the team will spend the coming months further developing their robot and AI model to prepare for mimic’s official product launch this year.