From riverbeds to flood zones: new sonar tech puts Australia on the map

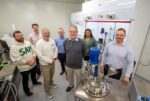

An Australian designed and built sonar sensor capable of operating in shallow water and coastal environments has been developed by Macquarie and University of Wollongong researchers. The Smart sonar and accessible hydrography project has progressed the local manufacturing of state-of-the-art transducers for high-sensitivity sonar systems, proving Australia need not rely so heavily on international suppliers. High-sensitivity sonar systems are vital for water managers, dam operators, mining sites, and environmental monitoring, enabling the mapping of riverbeds, tracking of sediment movement, and surveillance of underwater vegetation such as seagrass. The new transducer shows strong promise for surveying flooded and storm-damaged areas, and coastal environments. The project, supported by the NSW Smart Sensing Network’s Grand Challenge Fund, was led by Senior Lecturer in Macquarie University’s School of Computing, Dr Matthew Roberts. He contributed advanced signal processing and data analytics, enabling the sonar transducer to generate detailed maps and measurements of underwater environments in real time. “This project proves that Australia can develop underwater sonar technology from start to finish,” Dr Roberts said. “It’s not just about the hardware—it’s about the full capability, from ceramic design to field deployment, that allows us to build systems tailored to Australian needs.” At the heart of the system is a ceramic transducer—sometimes called a “ceramic puck”—which converts electrical energy into underwater sound waves. The piezoelectric ceramic material, developed by the University of Wollongong, is typically used in medical ultrasound and has now been adapted for underwater applications in Australia. Distinguished Professor Shujun Zhang from the Institute for Superconducting and Electronic Materials at the University of Wollongong is the co-investigator on the project. “This high-sensitivity transducer was built on a foundation of advanced, domestically fabricated piezoelectric ceramics, crucial for operating in complex shallow waters,” Professor Zhang said. “The project also strengthens vital sovereign capability by training the next generation of Australian material researchers in cutting-edge transducer design.” […]